In the past, when team convene to perform FMEA, there is a generic intuition that team members would draw on their experience when identifying failure modes. While past experience is a good source of reference, sole dependence on this as a source for identifying failure modes often leads to poor coverage for FMEA scope. This is a situation we call ‘spot coverage’ or ‘selective coverage’. For example when the scope of the FMEA involves ten processes, only six processes are covered as the remaining processes are perceived as ‘low risk’ by experience.

Imagine if the aircraft maker tell us that their FMEA team only focus on selective system of aircraft where failures have higher chance of occurring by their experience; the rest of the aircraft is not assessed due to perceived ‘low chance of happening’ during their FMEA. Would you be comfortable to take the next flight?

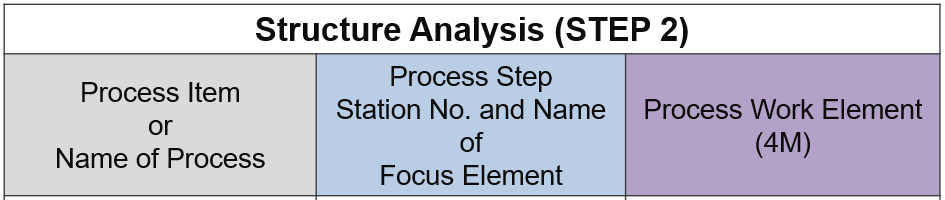

The above is the exact rationale that the new FMEA require us to develop a structure as step two right after we determine the scope in step 1. In step two for structure analysis, a three tier structure is built into the FMEA format. This three-tier structure continues through step 3 and 4 to provide a consistent platform for the analysis process to proceed in a systematic manner ensuring coverage is adequate and not compromised.

The new AIAG VDA FEA was published in July 2019. The above is one of the insights we share during our past 12 months of conducting AIAG VDA FMEA workshops with companies from the automotive supply chain.

If you wish to know more about FMEA, you may contact the author at contact@leoardent.com.